When installing a structure such as a solar carport, especially one viewed as an investment, one must always consider the associated costs projected over the lifetime of the structure. One of the most important factors to consider when looking at a structure’s lifetime costs is corrosion. Corrosion is constantly acting on a structure and is one of the largest impacting factors on the longevity of a structure. Corrosion rates determine the type of protective measures required to increase the longevity of a structure and additionally, the associated maintenance and repair costs. In order to get a rough idea of the cost of corrosion, one must have a general understanding of the process and all involved factors.

What is Corrosion?

Corrosion is the natural process of deterioration of metal components, this reaction is caused by the environment. A common type of corrosion is rust, which is found on steel and iron structures. Corrosion occurs when gas or liquid attacks an exposed section of a structure, in this case, water and oxygen. This can be accelerated by salts, acids, and warmer temperatures.

What Causes Corrosion?

Corrosion is an electrochemical reaction that appears in a few forms, such as chemical corrosion and atmospheric corrosion. Metals corrode when it reacts with another substance such as oxygen, hydrogen, or an electrical current. Additionally, when metals like steel are placed under too much stress it may cause the material to crack which can lead to accelerated corrosion. Anything that contains metal is susceptible to corrosion including the metal in photovoltaic components. Solar structures and PV modules are continuously exposed, resulting in structures degrading, and the modules losing efficiency over time. The corrosion can affect critical electronic connections within the panels, reducing the amount of energy being produced. PV modules are designed to last for decades as the solar cells and their electrical components are protected by sealants, encapsulating polymers, and strong tempered glass. Often, corrosion is not considered when evaluating the structure itself. What measures are taken to properly ensure a structure is properly protected?

How Corrosion affects Structures

Soil Corrosion

A major concern with solar ground mounts is the corrosion related to the pile being embedded in the soil. Piles are driven into the soil where they experience degradation over time due to soil corrosion and/or atmospheric corrosion. Soil corrosion on ground mounts is caused by aerated soils mixed with water, forming conductive liquids, and creating a reaction between anodes and cathodes. Another driving force is the different pH levels of soil which factor into corrosion because of increased or decreased acidity. The higher the pH level the more acidic the soil, which can potentially lead to high corrosion rates.

Soil corrosion is an effect of buried metals and/or concrete that is in direct contact with soil. Some of the most common influences soil corrosion has on metal or concrete structures is aeration, electrical conductivity, salt, moisture, and pH levels. Soils possess different levels of acidity, ranging from a pH of 2.5 to 10. A pH level of 7 is the neutral level of acidity that can minimize the possibility of corrosion. If pH levels reach 5 or below the corrosion rate is faster and can happen as early as installing process. Chloride ions are very harmful to metals because they have a direct role in the metal anodic dissolution. Chloride ions in soils can reduce resistivity. Sulfate is less corrosion to metal structures compared to chloride ions. The sulfate transforms into sulfides, which are highly corrosive due to anaerobic bacteria.

Aeration is described as air trapped in the soil. This is a major factor of corrosion because it affects evaporation and water retention rate. Soil that has higher rates of evaporation and lower water retention it is less prone to corrosion. The different types of soils play a role in determining the degree of aeration. Sandy soils have larger particles that permit faster evaporation and better aeration after water is introduced to the soil. The different colors of the soil can help you categorized aeration. Soils that have a yellow, brown, or red color have good aeration compared to gray soils that are unfavorable.

Atmospheric Corrosion

Atmospheric corrosion occurs from the air invading impurities of the steel piles. The atmospheric corrosion differs between geographic regions because of variations of humidity and contamination in the air. Moisture, whether in the form of dew, rain, or condensation, is a major factor in atmospheric corrosion. Rain can speed up the corrosion process through constant wetness, especially in areas with galvanized bolts and/or steel structures. For example, a tropical environment has higher temperatures and humidity. The corrosion rate is higher in these areas due to the constant presence of water, high humidity, and increased temperatures. Environments that have little to no moisture typically have a slower corrosion rate. When dew films become saturated with acidic sulfates, salt, or other acids, an electrolytic environment that accelerates corrosion is created.

Salt can settle on surfaces and reacts with water forming a slightly acidic solution, accelerating the process of corrosion. When salt is present it causes corrosion at high rates than water by itself. This is a large factor in coastal and marine environments that are notoriously corrosive.

What piles types to use in specific environments

Cold Rolled Piles

Cold rolled piles are a light gauge roll-formed pile that has been pre-coated with a G-90 galvanized coating. These piles have a thin coating that cracks when they are formed into piles. The cold-rolled piles should not be used in moist or corrosive soils, and additionally should be strictly limited to dry arid climates that have minimal rates of corrosion. They offer a 5-10-year lifetime period.

I-beam Piles

The I-beam piles are the most used piles. They have a wide range of profile thicknesses and can receive a wide range of galvanized coating thicknesses, often several times thicker than a G-90 spec’ coating. The galvanized coating applied can be increased to combat higher rates of corrosion offering increased protection. This pile is more robust which allows it to have a longer lifespan, often lasting around 12-17 years.

Concrete Encased Piles

The concrete-encased piles are standard cold-rolled or I-beams which are cast in place with concrete, instead of being directly driven into the soil. The concrete creates a barrier from the structure to the soil that can add additional protective barriers. This type of pile is very expensive and very labor intense, and should not be used in moist soils when the concrete can hold water, or in regions where there are large temperature fluctuations where the concrete can crack and expose the structure.

Coated Piles

Coated piles are standard piles coated in a protective coating of epoxy or paint. The coating can be applied to most pile profiles. This protective coating can be added to a galvanized structure or a raw metal structure. This protective coating offers a high level of protection that has few associated risks compared to the concrete-encased piles. The protective coating reduces installation time, as they can be directly driven into the ground.

Kern Solar Structures X-Piles

The solar industry has always battled with building structures that can hold up in corrosive soils. Sacrificial galvanized coatings have been the standard choice of piles. Kern Solar Structures created X-Piles™, an epoxy coated pile, to withstand extremely corrosive soils. The X-Piles™ is coated with at least 20 mils of our proprietary Envirolast 627™ epoxy coating, developed in conjunction with Sherwin-Williams, with a degradation rate of 1 mil per year. Our pile has a lifespan of 30+ years. Envirolast 627™ is engineered to be one of the toughest coatings in the market and can withstand being driven directly into the soil. If you want to learn more about X-Piles and the advantages they offer check out our website.

Corrosion and Solar Carports

Typically, carports experience fewer corrosive factors than solar ground-mount installations. This is because they are installed using foundations and never encounter soil. The main corrosive environment is atmospheric. This does not mean that carports do not corrode less or do not need to have ample corrosion protection. Atmospheric can cause just as much damage, and in some cases is overlooked or incorrectly evaluated which leads to a structure with a higher corrosion risk. This is especially apparent when structures are installed in marine or coastal environments.

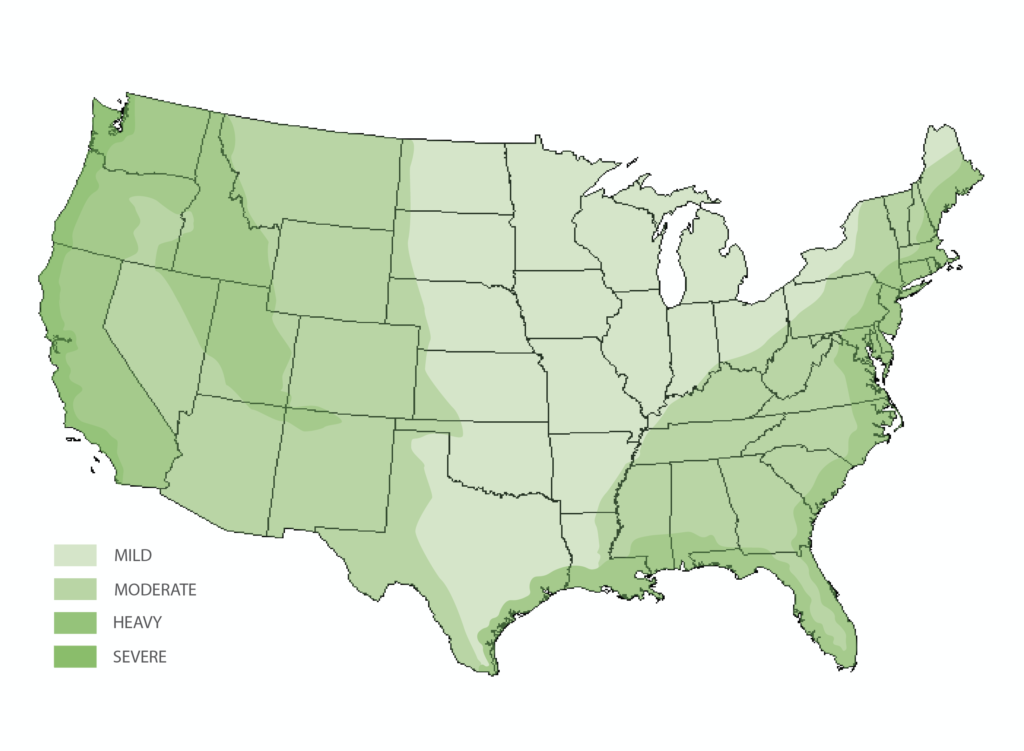

The easiest way to prevent this oversight is to reference corrosion maps. These maps show atmospheric corrosion trends by region and can be the first tool used to properly specify an appropriate protective or sacrificial coating.

Types of Coatings

One of the most important factors when specifying a coating for a carport is the type of coating. There are two main categories for coating types: Protective Coatings and Sacrificial Coatings. Protective coatings are most commonly paint. It forms a protective barrier that encapsulates the entire structural member and protects the structure underneath if the coating is present and intact. It can be repaired easily in the field and often includes warranties. The sacrificial coating is coatings the protect the structure underneath by corroding away. The most common sacrificial coating is Galvanization. This coating can be applied in various thicknesses to provide a longer service life. The downside to a galvanized coating is its inability to be effectively repaired in the field, and due to its sacrificial nature, if it is in a more corrosive environment it degrades at a faster rate, where in most cases a protective paint is not reactive and resists increased corrosion rates better.

What are the differences in carport structure types

Cold Rolled Carport Structure

A cold rolled carport structure is made of cold-rolled members (same material as a cold-rolled pile) and features a G-90 galvanized coating. One important factor to consider when using a cold-rolled structure is corrosion. The G-90 coating is applied before roll forming, so when it is formed, the galvanized coating cracks on the corners where the material is stretched. This causes the coating to be compromised before it is even installed. Due to this factor, as well as the thin gauge material used, cold-rolled structures do not combat corrosion effectively. Their uses should be restricted to dry arid climates with little to no moisture present. They have an effective service life of 10-15 years.

Structural Steel Carports

Structural steel carports utilize high strength architectural steel. These carports use larger and thicker individual pieces and are often more flexible in their application. Due to the method of fabrication, structural steel members are coated after the fabrication process, leading to an uncompromised coating. In addition to this, they are easier to paint and can receive thicker galvanized and painted coatings without the threat of warping from heat. Structural steel carports can receive a wide range of coating and thicknesses and are better suited for highly corrosive environments. They often have a service life of 20+ years.

Kern Solar Structure’s Solar CarPorT System

The Solar Carport system is a structural steel carport that takes advantage of Kern Solar Structures in-house coatings capabilities. Kern Solar Structures offers warrantied protective coatings with a wide range of coating types. This includes coating types from simple urethane coatings, to extremely durable marine epoxy. By properly spec’ing a coating, the Solar CarPorT system can last 30+years.

The Cost of Corrosion

While it is hard to place a specific value on corrosion, it is important to factor in corrosion to the cost of any solar project. By properly spec’ing a coating on a structure, repair and maintenance costs can be minimized, protected by a warranty, and push the service life of the structure past the estimated time frame. If a structure is improperly protected, it can lead to increased maintenance and repair costs, and in some cases serious structural damage. When this is the case, major structural repairs must be made, and sometimes the entire structure must be replaced. When this happens, the cost can quickly climb to several thousand dollars, or double the initial project cost if the structure needs to be completely replaced.

To stay up to date with Kern Solar Structures' blog, product updates and solar news subscribe the the Newsletter!

You must be logged in to post a comment.