What is the PV Module?

A PV module is created by a series of connected solar cells that provide standard output power. The PV module is encapsulated with tempered glass or other transparent material on the front surface, and with a protective and waterproof material on the back. The edges are sealed for weatherproofing, and there is a frame holding everything together in a mountable unit. In the back of the module, there is an electrical box, or wire leads, providing electrical connections. These panels are created to absorb sunlight as a source of energy to generate electricity. The electricity created from solar cells has become one of the most cost-efficient energy sources.

Solar PV modules have aluminum frames that are attached directly to the silicon. Solar panel framing plays a fundamental role in increasing mechanical strengths as well as making the installation process easier. It is important to know the different types of framing options, there is the full-frame, partial frame, and bifacial frame. At Kern Solar Structures our structures can only support full-framed panels, this is due to our Solar Speed RaX™.

The different types of PV Modules

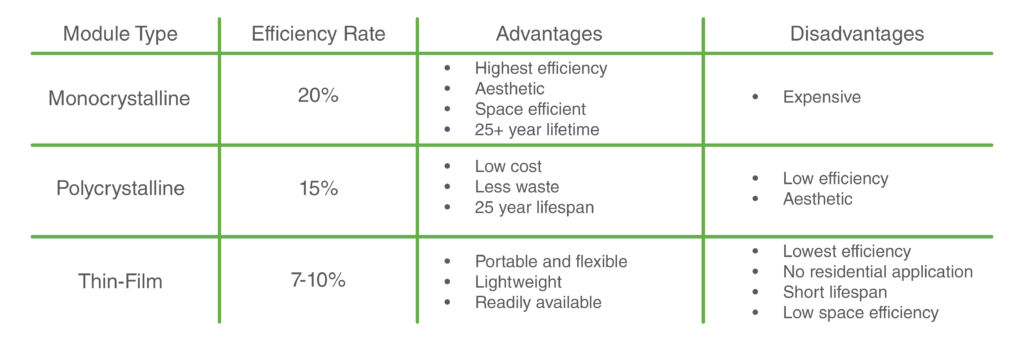

Solar PV manufacturers are continuously looking for different ways to make solar cells more efficient, so there are different types of panel technologies, offering varying levels of efficiency and reliability. Although there are many different types of modules the three most prevalent module types are monocrystalline, polycrystalline, and thin film. Each of these modules serves different purposes and needs, the graph below is a quick overview of each panel in comparison to one another.

Monocrystalline

The monocrystalline panel is known to be the premium level PV module. These modules can easily be recognized from the uniform black cells and the round edges. The monocrystalline module is called “mono” to indicate the single-crystal silicon allowing the electrons to generate a flow of electricity. Due to the cells being cut into a single source of silicon this results in monocrystalline being the most efficient module type. Monocrystalline modules have a high-power output reaching efficiency ratings around 20%, they occupy less space and last the longest. Another advantage is they tend to be less affected by high temperatures. While the modules are efficient, their manufacturing process is less sustainable due to creating more waste in comparison to the alternatives. This increases the cost production resulting in high cost for the end-user.

Polycrystalline

The polycrystalline modules are made of multiple silicon pieces that are blended together. This blend gives off a blue color from the light reflecting off the fragments in the cell. The polycrystalline solar panel is constructed from melted fragments of silicon formed into wafers. The manufacturing is cheaper due to less energy and materials being used which leads to a lower cost for end-users, creating a significant cost advantage over the monocrystalline modules. The polycrystalline modules have less freedom for the electricity to move due to multiple crystals in each cell, creating a lower efficiency compared to monocrystalline. Although the efficiency is lower the longevity of this module is substantial, surpassing 25 years of use. Polycrystalline modules are leading in the market because they are the best value; they are half the cost of a monocrystalline module while offering efficiency levels close to 15%.

Thin-Film

If you are looking for a less expensive option, you may want to look at the thin-film modules. They are lightweight and portable which makes them best utilized for projects with lower power requirements. Thin-film modules are constructed from a variety of materials. These cells are not made up of solid silicon wafers, rather composed of non-crystalline silicon placed on top of glass, plastic, or metal. To create thin-film modules, manufacturers place a layer of cadmium telluride between transparent conducting layers that help capture sunlight. Thin film technology is less expensive to manufacture making them more cost-effective at a larger scale. Although these panels are the easiest to produce, they are unsuitable for residential installations due to how much space they require. They are often used for commercial and industrial projects with the least amount of space restrictions.

Bifacial Solar Panel (own text box)

A bifacial solar panel can capture sunlight from both the front and the back of the panel. Often the bifacial panels have a transparent back so sunlight can go through the panel, reflect off the ground, and back up towards the solar cells on the backside of the panel. This allows the panel to produce more electricity than a traditional solar panel. The monocrystalline solar cells are most manufactured with the bifacial solar panels, although some polycrystalline bifacial panels exist as well.

To stay up to date with Kern Solar Structures' blog, product updates and solar news subscribe the the Newsletter!

You must be logged in to post a comment.