Are you looking for a solar support structure? If you are, you will need to decide between a conventional project-specific structure or a pre-engineered structure.

What is Pre-Engineering?

A pre-engineered structure’s intent is to offer a solution that efficiently satisfies a wide range of structural and design requirements and needs. While a pre-engineered structure might not be as customizable as conventionally designed solar structures, they do come with their own set of benefits. The major benefits of pre-engineered structures to the solar industry come from their reduced cost to produce and faster project cycle times.

These structures are standard solutions that offer set table sizes making it easy to choose which structure best fits your project’s needs. The structure is sized by module count with 18, 36, 54, 72, and 90 module options available and is engineered for specific locations to account for the environment your structure will live in.

Many solar companies have started offering both pre-engineered and conventional structures. This gives customers a chance to determine which structure best fits their needs.

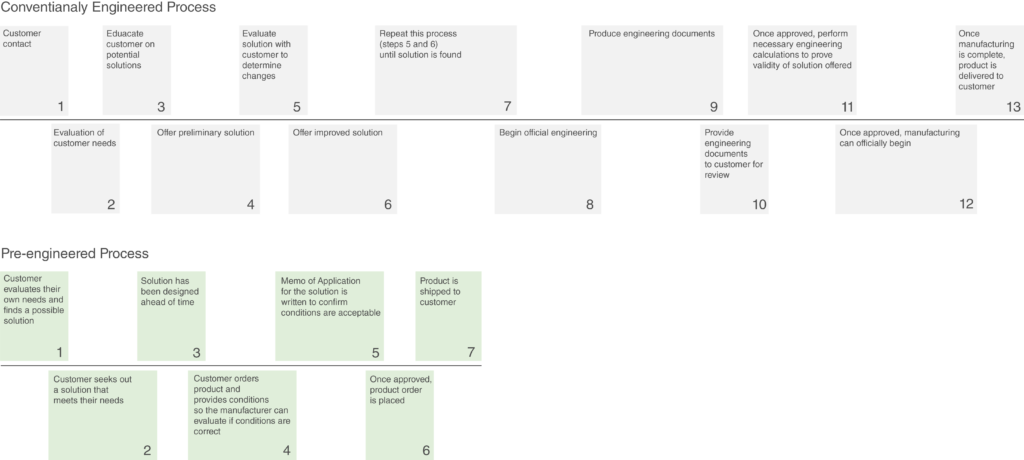

Typical processes for obtaining a conventional structure can take time due to the 13-step process customers usually have to go through. Compare this to a 7-step pre-engineered process that allows customers to get their structure in minimal time with a quicker and more efficient process.

One downfall of a pre-engineered structure is their lack of customization, so if the structure does not meet all a project’s requirements, a conventionally designed structure is the best option.

Conventional Engineering Process

Conventional engineering, also known as the traditional engineering method, is a step-by-step project-specific process. Many phases play into creating a structure that best fits a project’s needs.

The process starts with you, the customer, that reaches out with a problem in hopes to find a solution. When a possible solution is found, the customer can change or improve the solution. If improvements or changes are needed, adjustments are applied to create an improved solution.

Once a customer confirms this solution is best for them, the official engineering process can begin. The engineering process can vary on time due to the size, type, and industry this project lies in. Once engineering documents are produced, the customer reviews and evaluates them to be approved. After approval, a licensed engineer performs calculations and determines the validity of the design to properly achieve the desired solution.

The next step is manufacturing the structure itself. This takes time because of the different variables of the structure and site. Once manufactured, the structure is delivered and installed.

Many key components also play into this process, with solar panel choice playing a major role in the structure’s dimensions and configuration. A structure’s physical location is also critical in a structure’s design since environmental conditions (snow load, wind speed, soil conditions, etc.) play a major role.

For example, designing a structure to handle snow loads requires changes to account for the added weight of the snow. With snow loads varying widely from location to location, it adds even another layer of complexity to the design. In some cases, this process even requires additional structural elements to the project design that might increase project cycle times.

Pre-Engineered Process

The solar industry is evolving fast, while new technologies are continuously emerging, pre-engineering allows you to obtain a structure that best fits your project’s needs at a fast pace while offering a predictable cost. The pre-engineered process begins with picking a structure that offers the best solution to your needs.

This solution has been designed beforehand to meet a setlist of conditions. These conditions include shared location and panel information implemented within the design of the structure. Once a structure is ordered, the engineer generates a memo of application that confirms the intended use of this structure meets the requirements of the pre-engineered design. The project is then approved, and products and materials are gathered, assembled, and shipped. Since these structures are standard, in most cases, the inventory for the project is already on hand offering no additional manufacturing that needs to be completed. The structure may already be partially assembled and ready to ship the day an order is placed.

Pre-Engineering at Kern Solar Structures

Kern Solar Structures has implemented pre-engineering within several product lines, allowing you to purchase pre-engineered structures like the MaX™ Ground Mount Solution. The MaX™ Ground Mount was designed and manufactured to maximize the solar developer’s profits while speeding up the delivery time for commercial and utility structures. These pre-engineered ground mounts are efficient, powerful, and offer many key beneficial features. The integrated design combines a standard array of sizes offering you the opportunity to achieve your design goal.

Combined with the Solar Speed RaX™ system, the MaX™ offers a high performing racking system with proprietary integrated bonding and 3 mode PV module securement system. This design offers a premium solar support structure that is compatible with most Tier 1 PV modules. These premium structures provide high power density that delivers over 17% more power per acre than a conventional ground mount structure. With these completed structure designs, installation services are available. The MaX™ Ground Mounts are available for purchase now!

To stay up to date with Kern Solar Structures' blog, product updates and solar news subscribe the the Newsletter!

You must be logged in to post a comment.