Factors to consider when installing a carport

There are many factors to consider when installing a solar carport. The most important factors we think should be considered is the installation method, the speed of install, and the process of install. Each of these factors satisfies projects specific needs.

Install Process: Staggered or Complete

Staggering an installation means that structures are installed at different times instead of all at once. There are benefits to doing it both ways. Staggered installs require a smaller crew, less equipment, and more time. It can potentially save on soft costs and allows for portions of the parking area to remain usable while others are under construction. Complete installs go faster but require larger crews and more equipment. The project is completed faster but the entire parking area is off-limits during the duration of the project and can cause problems for businesses/facilities that rely on their associated parking spaces. Due to the speed and flexibility of both the Sol FasT Method and the Solar CarPorT System, both options are feasible and can be easily implemented based on specific needs to the benefit of the whole project.

General Installation method

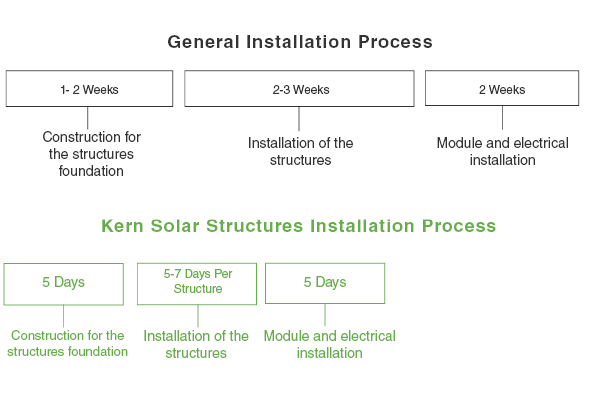

In many situations, solar carport installations are a lengthy and expensive process. In most cases, installation alone accounts for half of a project’s total expenses. This is due to the methodology that is typically used when installing solar support structures. The common process begins with constructing the structure foundation. Whether the structure is driven into the ground and set with concrete, or a pre-cast foundation with anchor bolts is used, this initial process can take anywhere from 1-2 weeks. If done incorrectly, there can be extensive delays. Once the foundation is complete, the rest of the structure can be installed. This typically includes columns, girders, purlins or beams, and the module racking system.

Depending on the type of structure, certain heavy equipment is required, such as cranes, forklifts, man lifts, and scissor lifts. This equipment significantly adds to the soft costs associated with the structure installation. Though this equipment is necessary for the installation, the complexity of the structure can increase the duration of the installation. Bolted and field-welded connections are the most common connections on solar carports, with bolted being the most cost-effective and least labor-intensive. Several types of structures have numerous bolted connections, each requiring dozens of bolts. Through these complexities, which may seem minuscule, numerous hours spent assembling and inspecting these connection points.

Depending on the size of the crew, this part of the process can easily take anywhere from 2-3 weeks, and sometimes longer for large projects. Once the structure is assembled, the PV modules and electrical components are installed and can take at least an additional week. In total, a typical solar carport installation takes 5-10 weeks depending on delays and adjustments and crew size.

Kern Solar Structures Installation Method

Our install method is the Sol FasT Method. It is a proprietary, patent-pending, method of installation that utilizes adjustable tripod stands to support the assembled column-girder assembly as it floats in the designated location, while the rest of the structure including PV modules, is assembled, inspected, and finally concreted in place. A set of two stands is required for every column-girder assembly in the structure, and the locations and set heights for each stand are provided for each structure. By flipping the installation process around, (typically it is setting columns, then pouring concrete and waiting 5-7 days for the concrete to set before the rest of the structure can be installed). The Sol FasT method can reduce structure install times from the commonly seen 5 weeks to only 5 days.

The speed of installation is determined by companies to install process. At KSS, our structures go up in about 3-5 days per structure. Due to the pre-drilled, no field weld, bolt-together assembly of the Solar CarPorT System, it is quickly assembled and placed upon the Sol FasT stands. The structure, including PV modules, and electrical work can then be installed before concrete is poured. This allows the use of a smaller crew. Due to the speed of our installation process, it reduces soft cost because it allows the installer to have more control over the project. Since our structures go in as a staggering install, this allows the lot to stay in use because only small parts of the lot will be under construction at a time.

When installing a solar carport, it is important to consider the installation method. Companies installation methods vary, the general installation process often takes time, this process can range from anywhere between 5 to 10 weeks. In most cases, installation accounts for half of a project’s expenses. Depending on the type of structure, certain heavy equipment is required, such as cranes, forklifts, man lifts, and scissor lifts. This equipment adds to the soft costs associated with the structure installation. The equipment is necessary for the installation, the complexity of the structure can increase the duration of the installation. The installation speed can vary due to the number of people working on the crew as well as having access to all equipment with no delay time. At Kern Solar Structures, we created an installation process our competitors cannot beat. Our installation time reduced from 5 weeks to 5 days, our pre-drilled, no field weld, bolt-together assembly of the Solar CarPorT System allows us to make this happen. We have a staggered install which allows the lot to stay in use because only parts of the lot will be under construction. This design allows a smaller crew to be used, which leads to a reduction in soft cost because it allows the installer more control over the project.

To stay up to date with Kern Solar Structures' blog, product updates and solar news subscribe the the Newsletter!

You must be logged in to post a comment.